Note: This text has been automatically extracted via Optical Character Recognition (OCR) software.

Die Engraving, Sinking, And Multiplying. By Mr. J. Newton, Royal Mint.

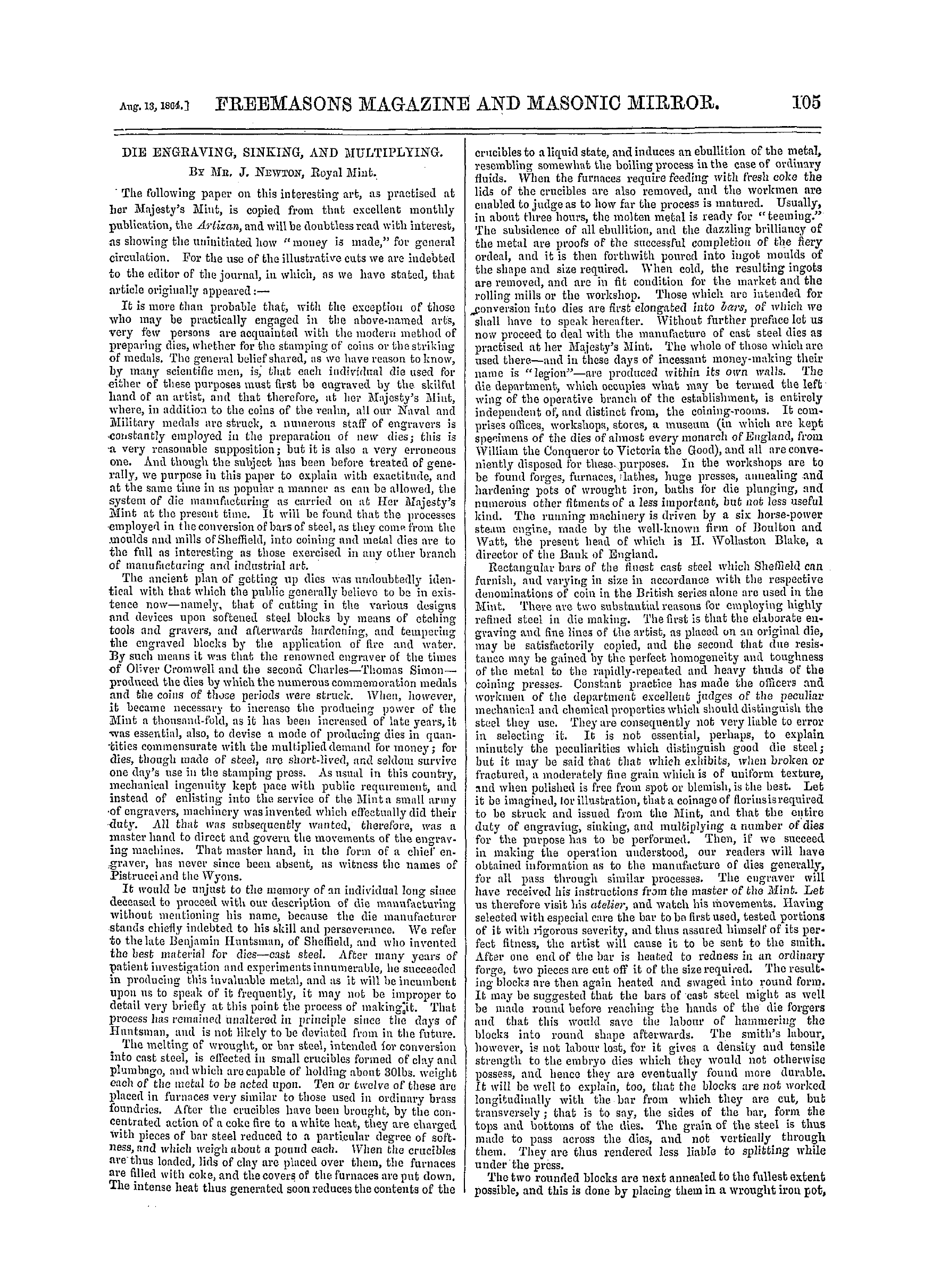

stage very hard , and it becomes necessary to anneal them . Tin ' s is effected by burying them in iron pots containing animal charcoal , and submitting the whole for many hours to the heat of coke furnaces . Subsequentl y , the blocks are allowed to cool

FIG . 2 . FIG . 1 . gradually among the ashes and cinders of the furnaces , and are then ready for tbe turning-room and the lathe ; here they are topped , as it is termed—that is to say the conical end of each is turned bright and prepared for its impression . After this operation they assume the appearance indicated by Fig . 4 , and are removed to the die multiplying press , which is similar in form ancl arrangement to that already described . The

press-FiG . 5 . . FIG . i . FiG , 3 . . man now steps into his hole , and is surrounded by perhaps a hundred topped die blocks . He affixes now the puncheon in the press , ancl attendants await his signals to raise the fly-arms , and release them as before described . One by one the blocks are placed so as to receive the impact of the puncheon until 4 he whole have received a partial impressionand present the

, appearance sketched in Fig . 5 . Occasionally , faulty steel is -discovered at this stage , and then the defective blocks showing , perhaps , fissures down their sides , are at once cast away to tlie scrap-heap . Those which exhibit no such symptoms of weakness are returned for another annealing , and will not be again put under the press until the following day . Of course at the Mint dies are continually being manufactured , and each

succeeding die sees fresh crops advancing step by step towards completion . AA ' e will imagine , therefore , that a moment after the departure of the batch just referred to , to the annealing ovens , another detachment , which were on the day before pnrtly struck , is returned to the die press-room . Then the puncheon , removed ancl placed successively on the half struck dies , has administered to it in succession the heavy blows of the press , care being taken first to fit in the engraving properly , and thus » to prevent the marring of the transfer . At this point the puncheon and embryo die are correctly exhibited by Fig . G .

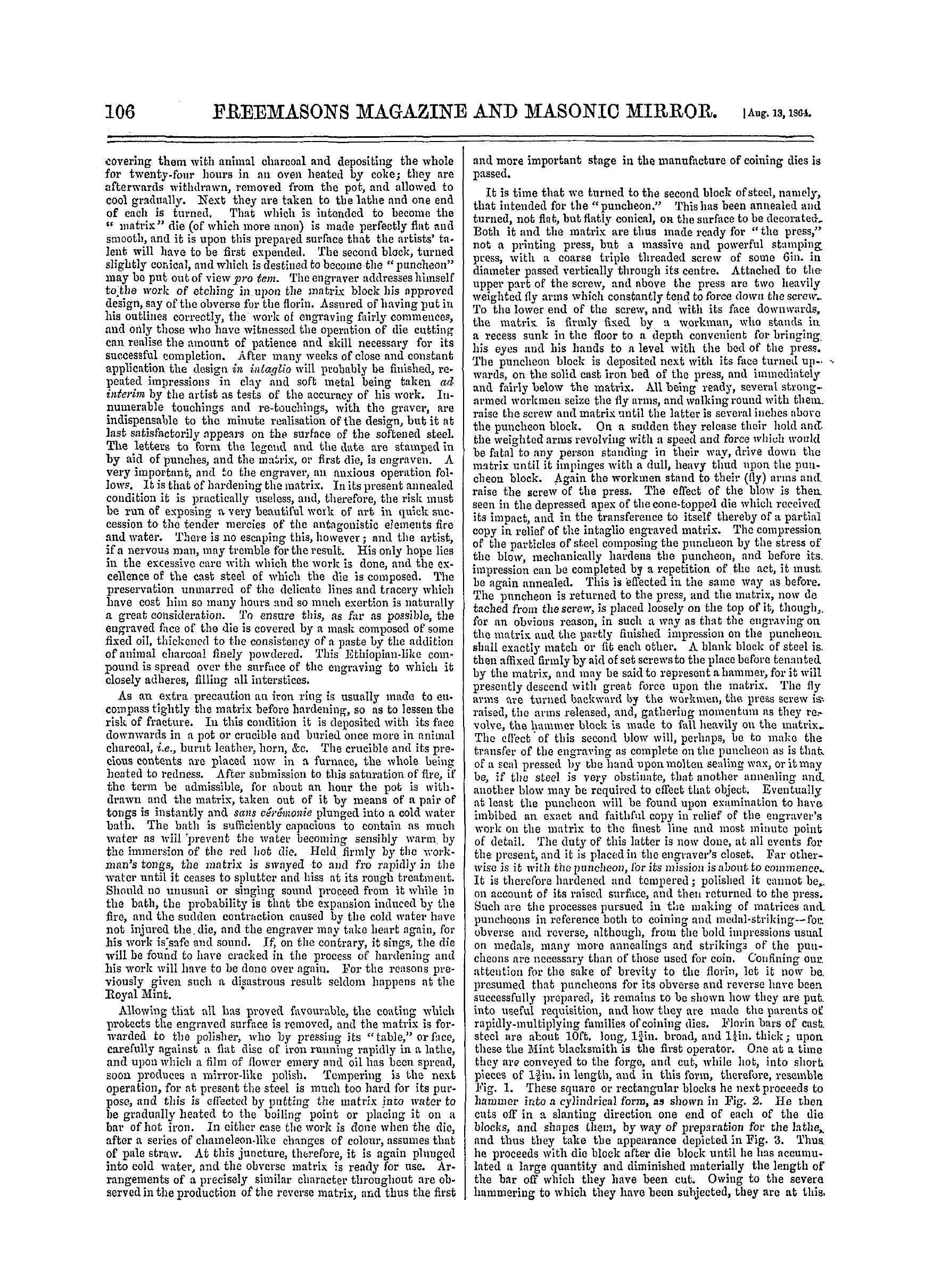

FIG , 6 . 'When separated , the latter assumes the appearance shown in $ Ii g- J " - Possibly , a third annealing and a third striking may

be required ; bufc this , of course , depends on the stubbornness or the plasticity of the steel , and with regard to medal multiplying that demands infinitely more labour . Fig . 8 will convey a clear idea of the florin clie when its impression is fully developed

FIG . 9 . FIG . S . FIG . 7 . We may now be considered to have reproduced , as it were 100 matrices by sheer mechanical and unarfcistic agencies , for the partially formed dies are really fac-similies of the engraver ' s handy work , and it will be understood that thousands and tens of thousands of dies may be ancl are pressed into existence at the Mint in the same way . The power indeed of multiplying copies in this manner is illimitable , for if the puncheon fails

either by cracking or sinking , there is the matrix to refer to for the creation of another , while if the matrix itself should break down one of the impressed dies may be used as a substitute for that , and thus , therefore , if the matrix and the puncheon be once successfully completed , whether for coins or medals , a power of reproduction exists in both which obviates all risk of requiring the engraver ' s aid to renew them . The wholly-struck dies are once more annealed and transferred to

the turning-room ancl the lathes . Each one is put into a peculiarly formed chuck fitted with adjusting screws , and so fastened as that the impression is made to run truly . Then all superfluous metal is cut away by sharp tools used by expert workmen , and are thus brought to gauged diameters . They then presentthe formindicatedbyFig . 9 . Afterwards come the hardening , polishing , ancl tempering processes as previously explained , and the whole batch is now readfor the coining press room

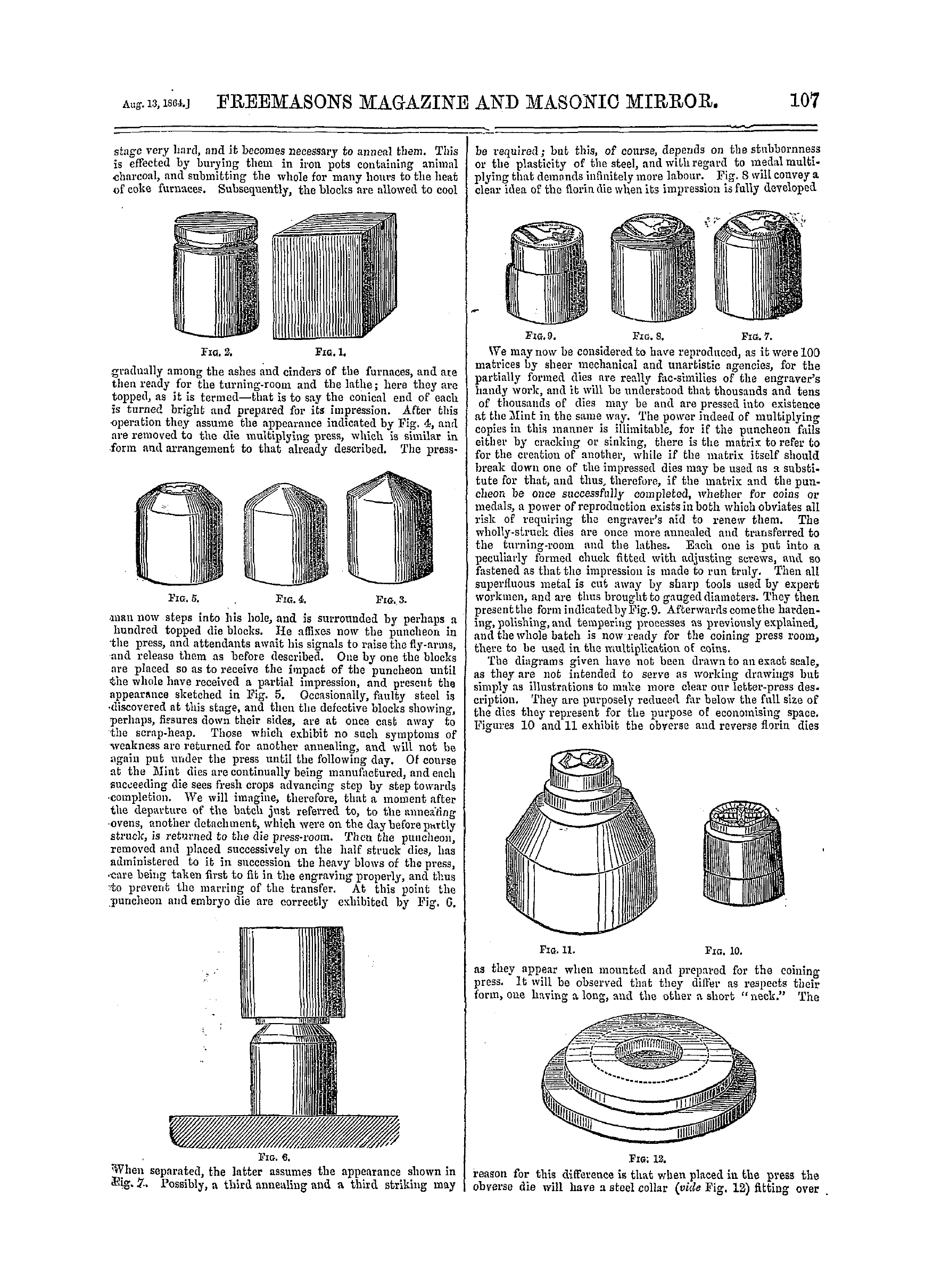

y , there to be used in the multiplication of coins . The diagrams given have not been drawn to an exact scale , as they are not intended to serve as working drawings bufc simply as illustrations to make more clear our letter-press description . They are purposely reduced far below the full size of the dies they represent for the purpose of economising space . Figures 10 and 11 exhibit the obverse and reverse florin dies

FIG . 11 . FIG . 10 . as they appear when mounted ancl prepared for the coining press . It will be observed that they differ as respects their form , one having a long , and the other a short " neck . " The

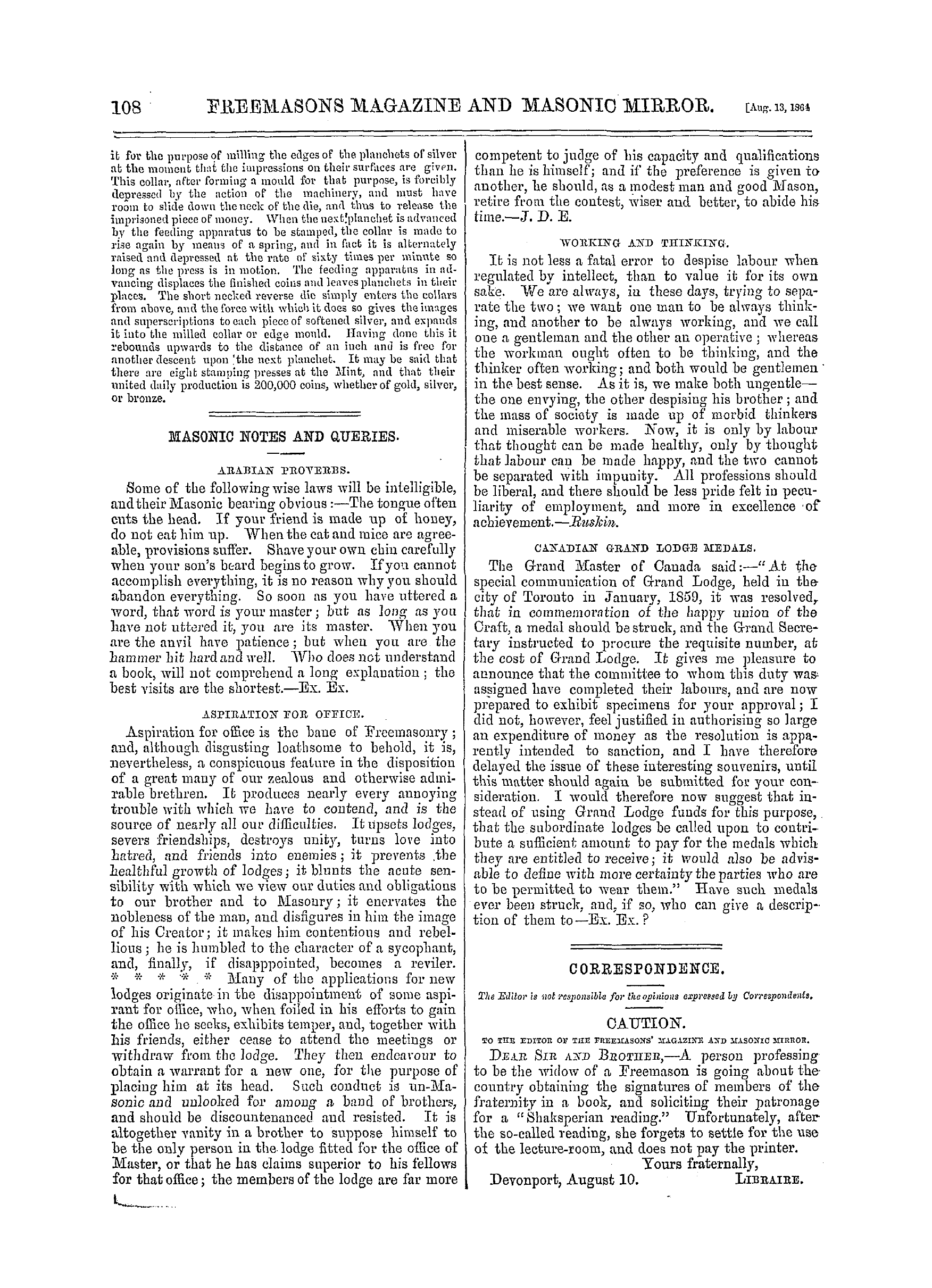

FIG ; 12 . reason for this difference is that when placed in the press the obverse die will have a steel collar ( vide Fig . 12 ) fitting over

Note: This text has been automatically extracted via Optical Character Recognition (OCR) software.

Die Engraving, Sinking, And Multiplying. By Mr. J. Newton, Royal Mint.

stage very hard , and it becomes necessary to anneal them . Tin ' s is effected by burying them in iron pots containing animal charcoal , and submitting the whole for many hours to the heat of coke furnaces . Subsequentl y , the blocks are allowed to cool

FIG . 2 . FIG . 1 . gradually among the ashes and cinders of the furnaces , and are then ready for tbe turning-room and the lathe ; here they are topped , as it is termed—that is to say the conical end of each is turned bright and prepared for its impression . After this operation they assume the appearance indicated by Fig . 4 , and are removed to the die multiplying press , which is similar in form ancl arrangement to that already described . The

press-FiG . 5 . . FIG . i . FiG , 3 . . man now steps into his hole , and is surrounded by perhaps a hundred topped die blocks . He affixes now the puncheon in the press , ancl attendants await his signals to raise the fly-arms , and release them as before described . One by one the blocks are placed so as to receive the impact of the puncheon until 4 he whole have received a partial impressionand present the

, appearance sketched in Fig . 5 . Occasionally , faulty steel is -discovered at this stage , and then the defective blocks showing , perhaps , fissures down their sides , are at once cast away to tlie scrap-heap . Those which exhibit no such symptoms of weakness are returned for another annealing , and will not be again put under the press until the following day . Of course at the Mint dies are continually being manufactured , and each

succeeding die sees fresh crops advancing step by step towards completion . AA ' e will imagine , therefore , that a moment after the departure of the batch just referred to , to the annealing ovens , another detachment , which were on the day before pnrtly struck , is returned to the die press-room . Then the puncheon , removed ancl placed successively on the half struck dies , has administered to it in succession the heavy blows of the press , care being taken first to fit in the engraving properly , and thus » to prevent the marring of the transfer . At this point the puncheon and embryo die are correctly exhibited by Fig . G .

FIG , 6 . 'When separated , the latter assumes the appearance shown in $ Ii g- J " - Possibly , a third annealing and a third striking may

be required ; bufc this , of course , depends on the stubbornness or the plasticity of the steel , and with regard to medal multiplying that demands infinitely more labour . Fig . 8 will convey a clear idea of the florin clie when its impression is fully developed

FIG . 9 . FIG . S . FIG . 7 . We may now be considered to have reproduced , as it were 100 matrices by sheer mechanical and unarfcistic agencies , for the partially formed dies are really fac-similies of the engraver ' s handy work , and it will be understood that thousands and tens of thousands of dies may be ancl are pressed into existence at the Mint in the same way . The power indeed of multiplying copies in this manner is illimitable , for if the puncheon fails

either by cracking or sinking , there is the matrix to refer to for the creation of another , while if the matrix itself should break down one of the impressed dies may be used as a substitute for that , and thus , therefore , if the matrix and the puncheon be once successfully completed , whether for coins or medals , a power of reproduction exists in both which obviates all risk of requiring the engraver ' s aid to renew them . The wholly-struck dies are once more annealed and transferred to

the turning-room ancl the lathes . Each one is put into a peculiarly formed chuck fitted with adjusting screws , and so fastened as that the impression is made to run truly . Then all superfluous metal is cut away by sharp tools used by expert workmen , and are thus brought to gauged diameters . They then presentthe formindicatedbyFig . 9 . Afterwards come the hardening , polishing , ancl tempering processes as previously explained , and the whole batch is now readfor the coining press room

y , there to be used in the multiplication of coins . The diagrams given have not been drawn to an exact scale , as they are not intended to serve as working drawings bufc simply as illustrations to make more clear our letter-press description . They are purposely reduced far below the full size of the dies they represent for the purpose of economising space . Figures 10 and 11 exhibit the obverse and reverse florin dies

FIG . 11 . FIG . 10 . as they appear when mounted ancl prepared for the coining press . It will be observed that they differ as respects their form , one having a long , and the other a short " neck . " The

FIG ; 12 . reason for this difference is that when placed in the press the obverse die will have a steel collar ( vide Fig . 12 ) fitting over